Zinc acrylate

Product alias: Zinc acrylate salt; Zinc diacrylate; Zinc acrylate

Cas No:14643-87-9

EINECS:238-692-3

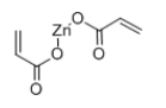

Structural formula:

Technical indicators:

Appearance: White powder particles

Content: 99%

Heating reduction: ≤ 0.5%

Fineness: ≤ 180μm

Packaging: Use a 25kg lined woven bag with the bag opening tightly sealed; Or cardboard drum packaging.

Storage: It should be stored below 30 ° C, away from heat and fire sources, waterproof and moisture-proof, and at a height of 0.5 or more above the ground.

Product image:

Application of Zinc Acrylic Acid:

Used as a peroxide bridging agent to increase crosslinking density, improve vulcanization speed, shorten vulcanization time, and also enhance bonding performance with metals.

Vulcanized products can obtain salt cross-linking bonds, increase product hardness, significantly improve flexural performance, and enhance elasticity.

Zinc acrylate is a multifunctional compound that has been widely used in various fields due to its excellent antibacterial properties and chemical stability. Main application areas:

Rubber industry:

In the rubber industry, zinc acrylate is an important rubber additive widely used in various rubber products. It mainly acts as a crosslinking agent in rubber, reacting with the double bonds on the rubber molecular chain to form a three-dimensional network structure, thereby improving the weather resistance, oil resistance, and wear resistance of rubber. Meanwhile, zinc acrylate also has a certain plasticizing effect, which can improve the processing performance of rubber.

Zinc acrylate has strong thermal hardening effect and is also used as a crosslinking hardening agent for golf ball centers, which can greatly improve hardness and elasticity. It is applied in the manufacture of solid golf balls, which can increase the impact rebound of finished products, as well as the uniformity of hardness and weight of golf balls, including rubber products such as bowling balls.

Coatings and adhesives:

Zinc acrylate is also widely used in coatings and adhesives. It can improve the weather resistance and corrosion resistance of coatings, enabling them to maintain good performance even in harsh environments. In addition, zinc acrylate can also be used as a modifier for adhesives to improve their bonding strength and durability.

Other applications:

In addition to the aforementioned fields, zinc acrylate also has applications in multiple other areas, such as:

Cosmetics: Zinc acrylate can be used as a preservative and skin protectant in cosmetics, improving product stability and safety.

Electronics industry: In the electronics industry, zinc acrylate can be used to manufacture conductive and insulating materials, improving the performance and reliability of electronic products.